So, I got home tonight, determined to get a chunk of work done on the legs. I want to get some gear in place for the thing to sit on, so it's doesn't rock and skate around (in theory at least). But you are right, Mr P, so I worked like a crazy man...

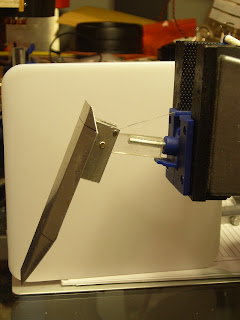

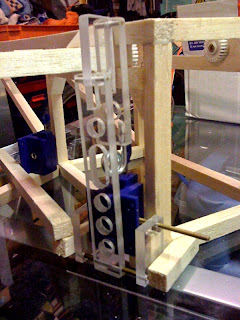

I got the rear vertical pieces cut out, sanded, drilled and tapped, then drilled the Alu knees of the rear pair. In a flash of genius I solved the anchor and adjustment problem for the tensioners, so they now operate correctly. I've ditched the LEDs too (for now).

I can lock-out the gear (manually locked in deployed position) and move on...

|

| Everything will need dressing up a bit. |

Time to work towards a controlled lift-off and touch-down cycle.