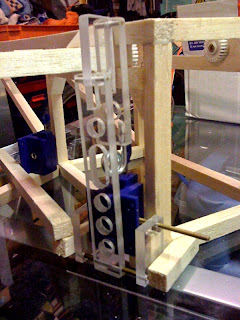

I've reworked the nacelle steerer setup because I wasn't happy with the gears, and it wasn't working as I'd planned. The servos used here are old cheapo ones but one is modifed to work in reverse. I can't remember how I did this (I'll post it when I remember) but it was convenient as the same signal can applied to both servos to make the nacelles turn the same way.

The first front leg is fixed in place and a rear one is getting there. I abandoned the vertical offset angle just for simplicity, as I'd like to move on to the flight systems.

Next: finish L/G and start on tail.